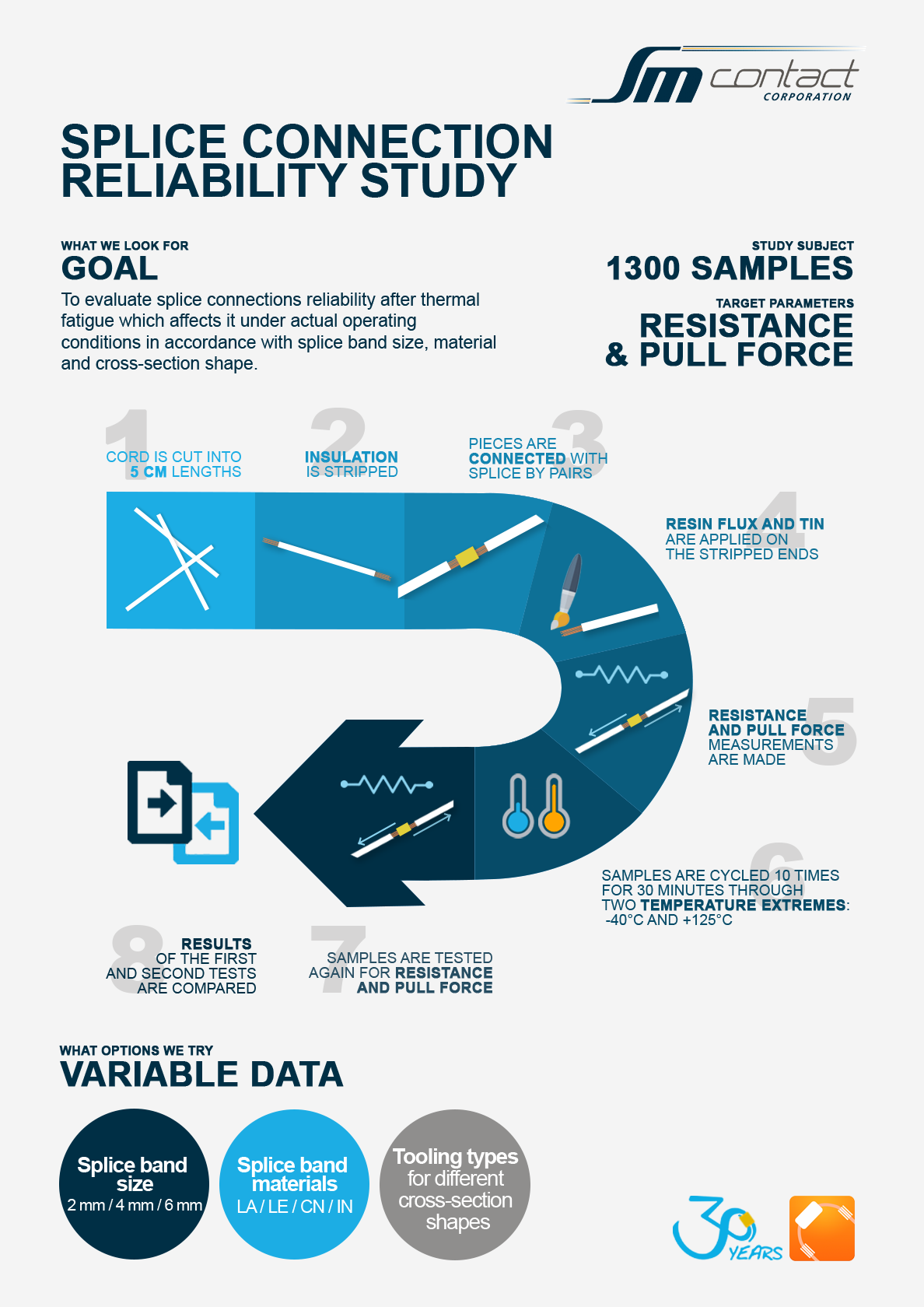

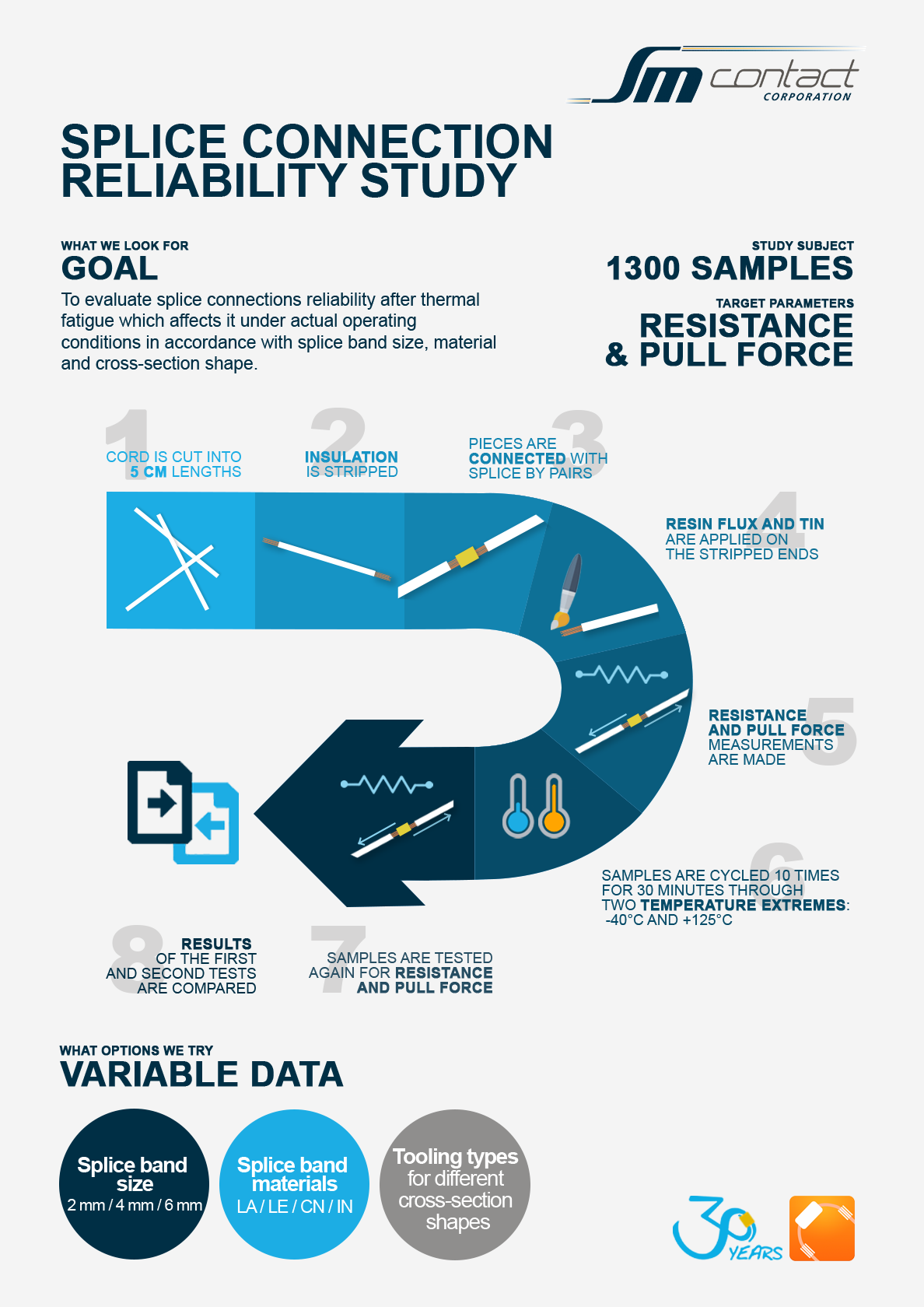

Do you know why no existing norm can be applied for a splice connection? To give you fine-grained explanation SM Contact Engineering has launched a study involving 1300 samples to be made and tested for resistance and pull force before and after thermal cycling.

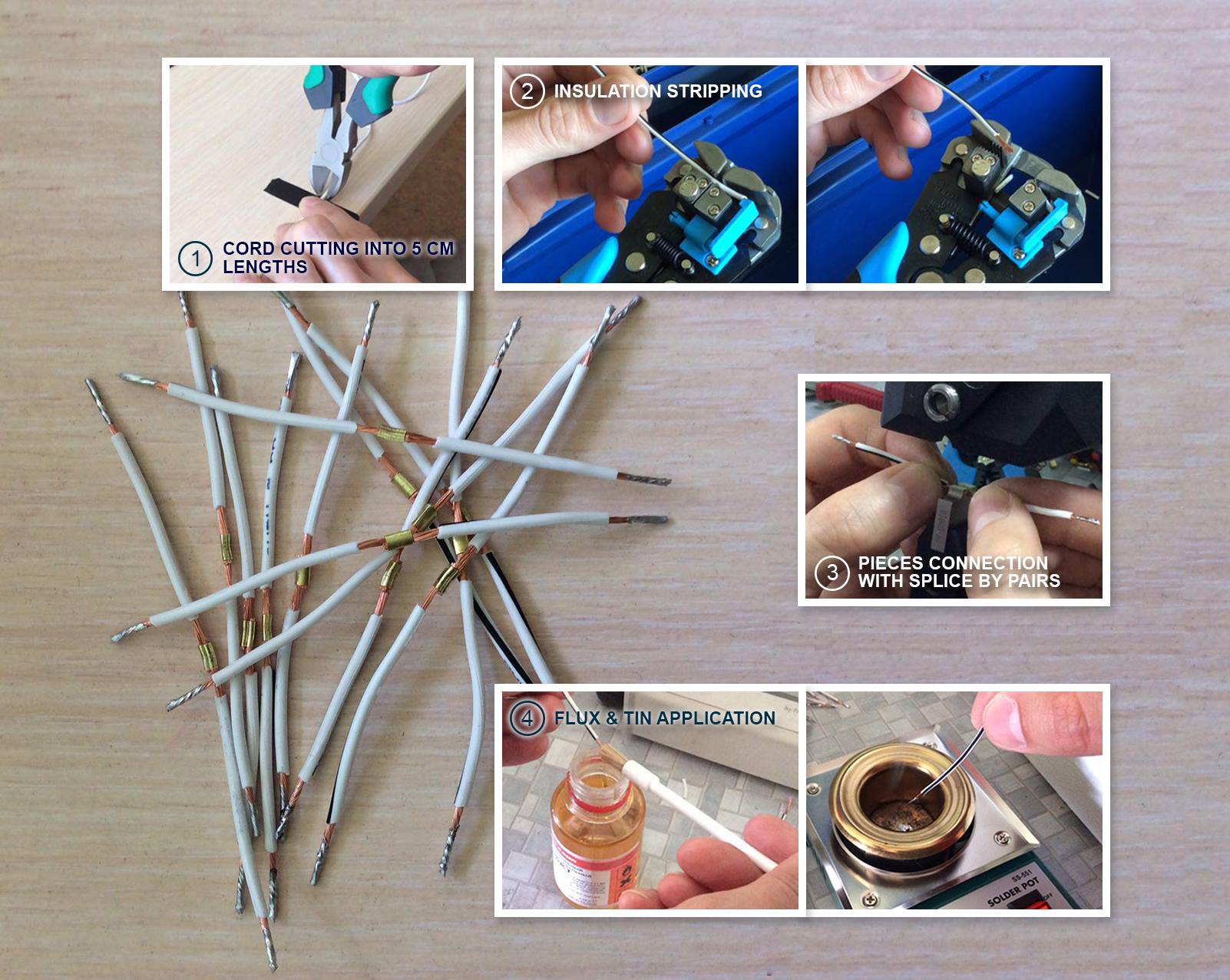

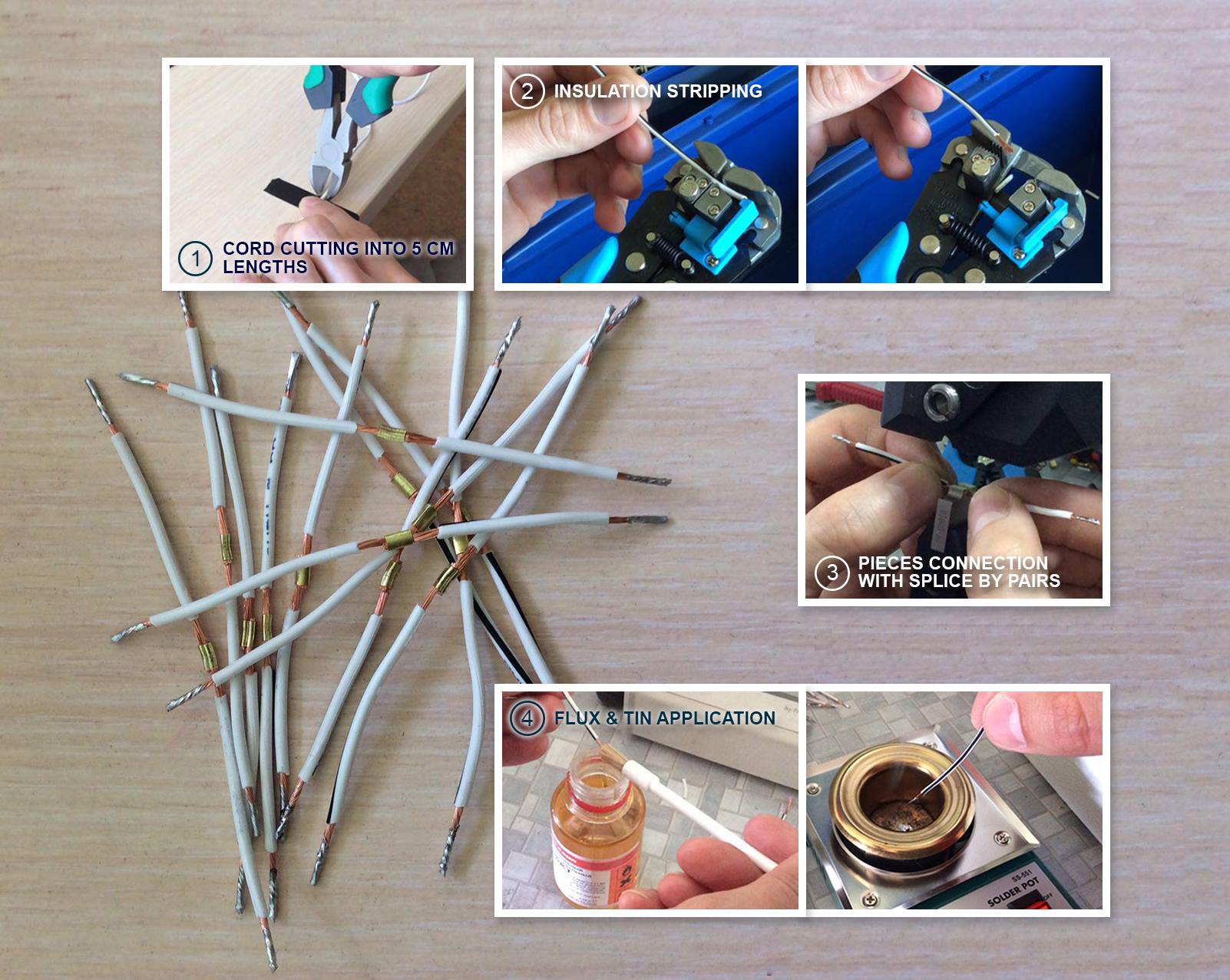

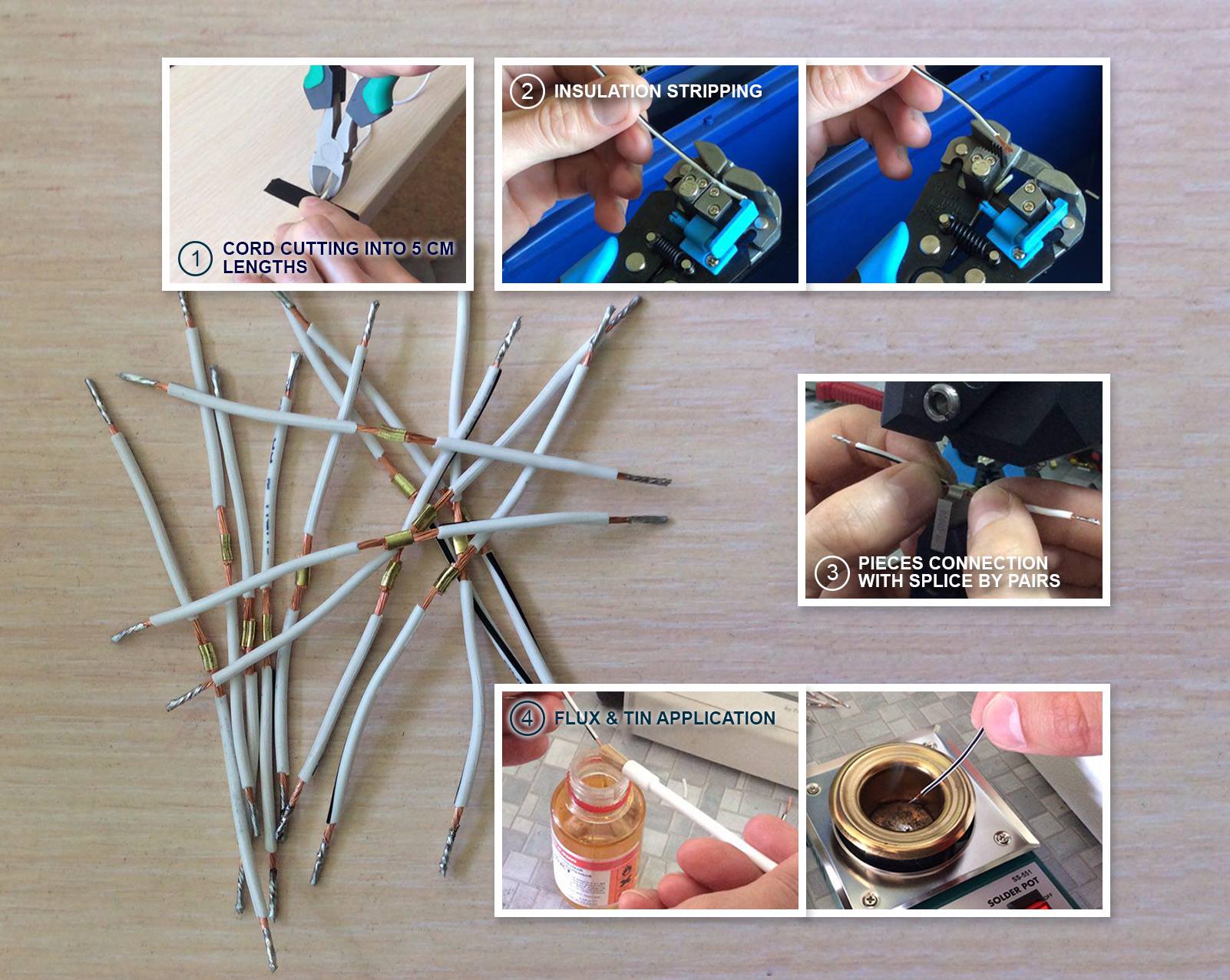

At the preparatory stage 1300 samples were made from 5 cm long cords (

STEP #1. CORD CUTTING). On purpose to get outcomes appropriate to several application fields, SM Contact tests various splice band sizes (2 mm, 4 mm, 6 mm) and materials (bright brass (LA), tinned brass (LE, SN 3-6 μ on nickel 1-3 μ), cuprum-nickel (CN), stainless steel (IN)), as well as tooling types for two cross-section shapes.

After the insulation is stripped (

STEP #2. INSULATIONS STRIPPING), pieces are connected by pairs with SM Contact own-brand splice of all the above-mentioned types (

STEP #3. SPLICE CONNECTION). SM Crimp 2000 is used to perform crimping.

To prevent insignificant processes that could influence on the target parameters flux and tin are applied on the stripped ends of the ready samples (

STEP #4. FLUX & TIN APPLICATION).

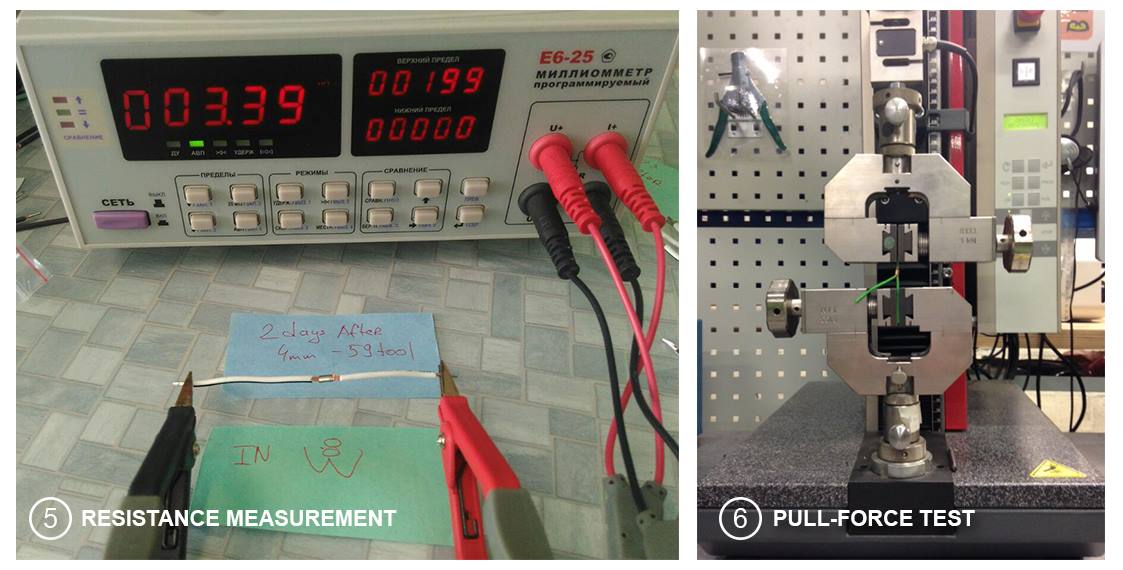

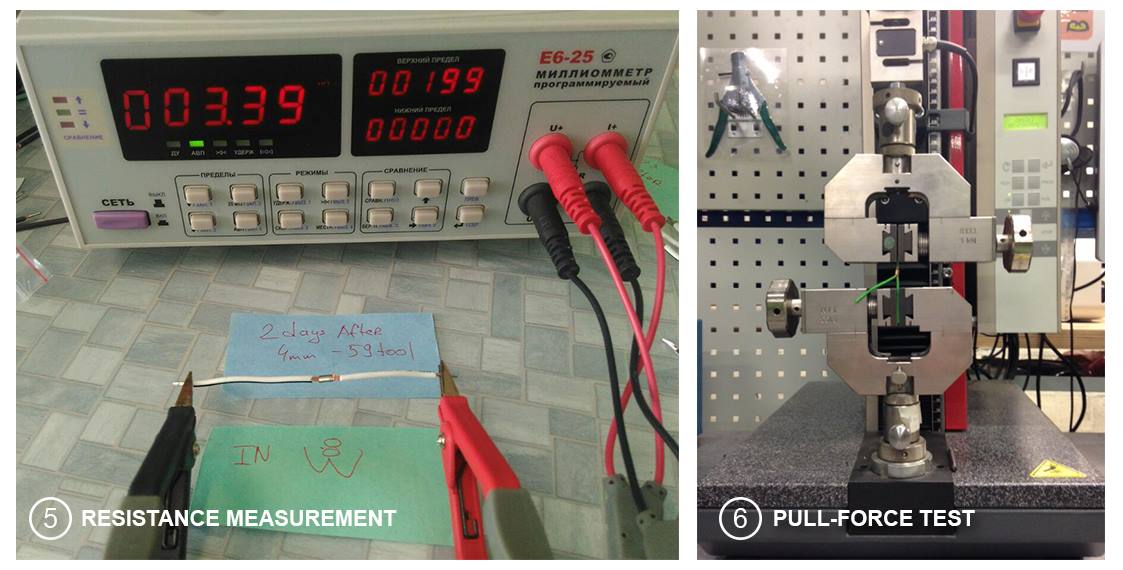

Next the first test comes: resistance and pull force measurements (

STEP #5 AND #6) are made to record the parameters before thermal fatigue.

Thermal stress is the most common cause of electronic devices’ failure. Various industries have different temperature ranges, which must be consider while developing the application. Thus temperature cycling that follows (

STEP #7. THERMAL CYCLING) consists of 10 heating and 10 cooling cycles: -40 and +125. Each cycle lasts for 30 minutes.

Samples are tested one more time for resistance and pull force (

STEP #8 AND #9) after being impacted by temperature extremes. First and second tests’ comparison gives thorough understanding of connections reliability. It illustrates different splices’ capacity to retain their properties over appropriate environments conditions range.

In a week we will introduce first test results!

[caption id="attachment_2583" align="aligncenter" width="449"]

Splice connection reliability study[/caption]

[caption id="attachment_2580" align="aligncenter" width="449"]

At the preparatory stage 1300 samples are made from 5 cm long cords, the insulation is stripped, and flux and tin are applied.[/caption]

[caption id="attachment_2584" align="aligncenter" width="449"]

Resistance and pull force measurements are made to record the parameters before thermal fatigue.[/caption]

[caption id="attachment_2585" align="aligncenter" width="245"]

Thermal cycling that consists of 10 heating and 10 cooling steps 30 minutes each.[/caption]

Previous "Useful tips":

Next "Useful tips":

Сохранить Splice connection reliability study[/caption]

[caption id="attachment_2580" align="aligncenter" width="449"]

Splice connection reliability study[/caption]

[caption id="attachment_2580" align="aligncenter" width="449"] At the preparatory stage 1300 samples are made from 5 cm long cords, the insulation is stripped, and flux and tin are applied.[/caption]

[caption id="attachment_2584" align="aligncenter" width="449"]

At the preparatory stage 1300 samples are made from 5 cm long cords, the insulation is stripped, and flux and tin are applied.[/caption]

[caption id="attachment_2584" align="aligncenter" width="449"] Resistance and pull force measurements are made to record the parameters before thermal fatigue.[/caption]

[caption id="attachment_2585" align="aligncenter" width="245"]

Resistance and pull force measurements are made to record the parameters before thermal fatigue.[/caption]

[caption id="attachment_2585" align="aligncenter" width="245"] Thermal cycling that consists of 10 heating and 10 cooling steps 30 minutes each.[/caption]

Previous "Useful tips":

Next "Useful tips":

Thermal cycling that consists of 10 heating and 10 cooling steps 30 minutes each.[/caption]

Previous "Useful tips":

Next "Useful tips":

English

English

Chinese

Chinese

+86- 20-3992 0957

+86- 20-3992 0957