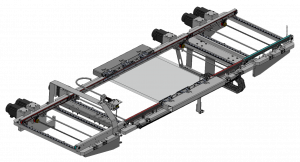

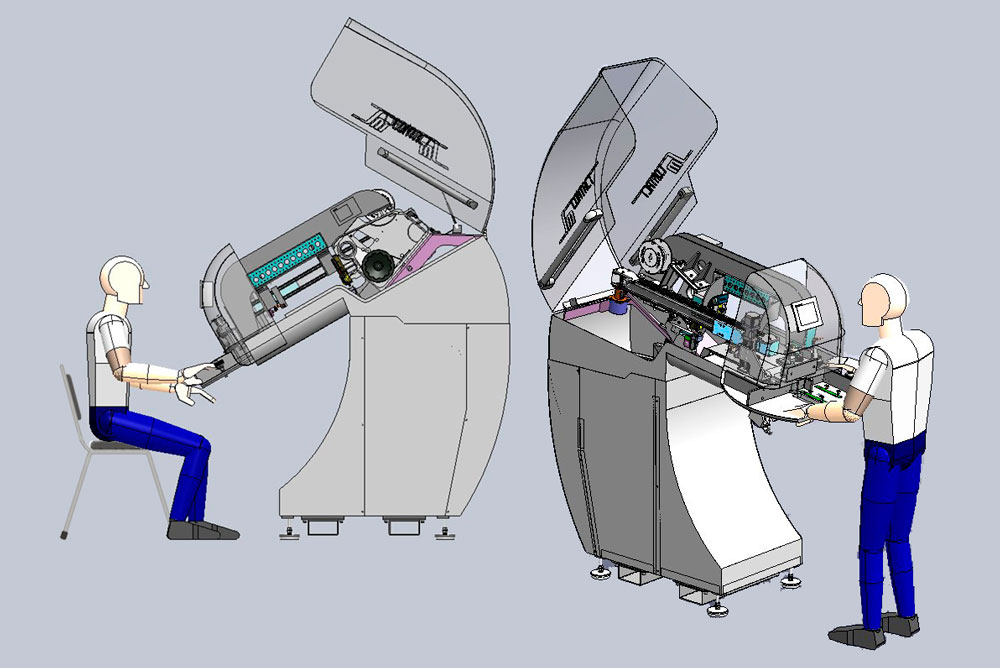

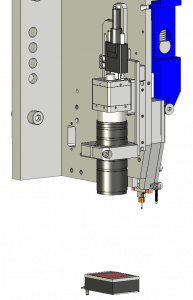

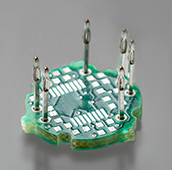

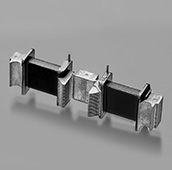

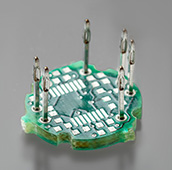

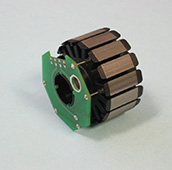

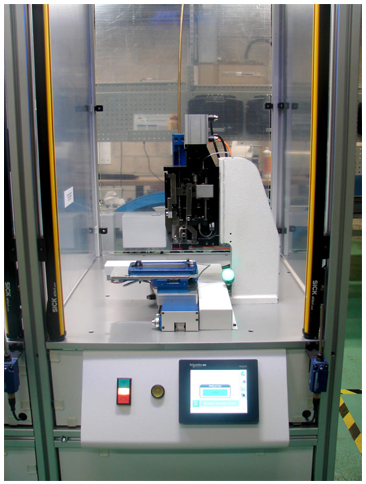

Pininsert 3200 (Conveyor Version) is equipped with SMEMA compatible belt conveyor system to enable the integration of equipment into the production line of surface-mounted printed circuit boards.

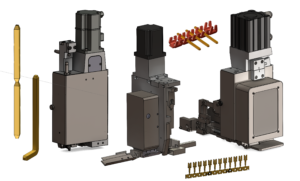

It can be manufactured as DH (Double-Head) version with two heads to insert pins of different dimensions within a cycle without readjustment.

English

English

Chinese

Chinese

+86- 20-3992 0957

+86- 20-3992 0957