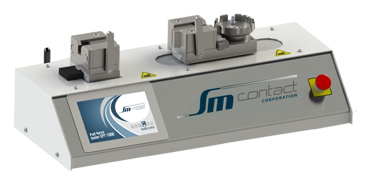

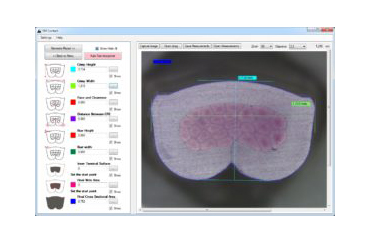

Mobile micrograph laboratory enables quick, user-friendly, reliable, and cost-effective quality assessment of a crimp or splice connection.

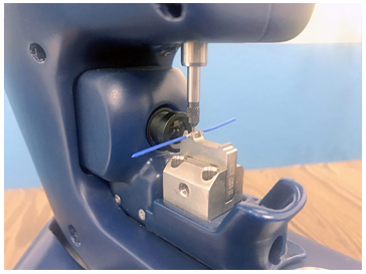

All the work steps are integrated in one device: first a sample is cut, its cross-section surface is grinded and etched to make necessary details visible, finally it is located under the optics to get macro image and to measure its parameters.

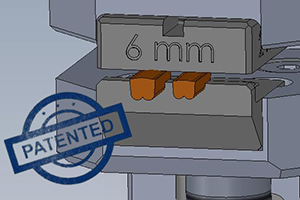

Brand-new sample holder assures proper sample positioning and makes transfer from one process stage to another easy and fast. One micrograph costs less than 1.00€ (example based on 10,000 micrographs incl. consumable materials).

English

English

Chinese

Chinese

+86- 20-3992 0957

+86- 20-3992 0957