Low insertion force simplifies the assembly and makes it cheaper.

Pressfit pins 0.50×0.40 mm, 0.60×1.00 mm, 0.60×0.60 mm are qualified in accordance to EN 60352-5. It proved to have required contact resistance (< 0.5 m?), acceptable deformations and resistance to rapid temperature changes and climate sequences.

Various pin press shapes allow large tolerances of hole diameter, which makes possible to select insertion and retention forces according to Customer’s demand.

Unlike solder joints pins can be designed to be removable to repair connection, if needed.

Instead of buying expensive connector, it is necessary to buy only pins that will fit Customer’s component.

Pin tip dimensions matches norms of such automotive manufacturers as BMW, GM, Daimler-Benz, PSA, VW, etc. Norms consider precut angle, rounding diameter, width and height of a pin tip.

Pin connection is adjustable in height and position, it can be inserted in necessary quantity into various components: PCB, plastic or metal connectors, coil frame, etc.

Thanks to automation it’s possible to insert up to 15000 pins per hour without any experience in pin interconnections.

Pin insertion doesn’t require additional soldering which means no thermal stress and no damage for components. As a result connection stays reliable under vibrations.

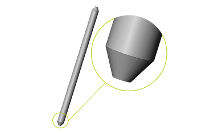

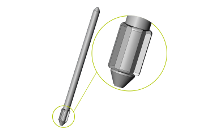

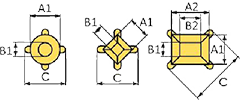

This simple-shaped type of pin has chamfers on both ends so that it can be used for connection purposes.

ApplicationCoil frame, printed circuits without metalized holes, over-molding, plastic components with drilled holes, metal components whose holes diameter has small tolerances.

Dimensions

| Wire shape | Square | Round | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| A1 | 0.3 | 0.4 | 0.46 | 0.5 | 0.71 | 0.91 | 1 | 1.14 | 0.5 | 0.63 | 1 |

| B1 | 0.2 | 0.25 | 0.25 | 0.25 | 0.35 | 0.45 | 0.55 | 0.6 | 0.3 | 0.3 | 0.4 |

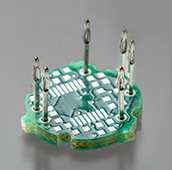

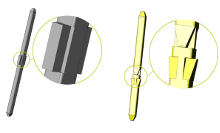

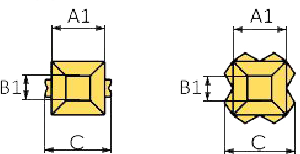

The Star pin is ideal for printed circuits with metalized holes to compensate holes diameter tolerances after drilling. It offers an excellent mechanical resistance and its shape is often used in “paste-in-pin and reflow” or “pin-in-paste and reflow” processes.

Its star shape, unlike the smooth pin, can be also used advantageously for round holes in plastic elements. When inserted, the smooth tip of a pin enters freely without any damage, while the star part provides its secure retention inside of a component thanks to its 4 peaks.

ApplicationSingle- or double-sided printed circuits, coil frame, plastic connectors.

Dimensions

| Wire shape | Square | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A1 | 0.3 | 0.3 | 0.4 | 0.4 | 0.46 | 0.46 | 0.5 | 0.5 | 0.63 | 0.63 | 0.71 | 0.71 | 0.91 | 0.91 | 1 | 1 | 1.14 | 1.14 |

| A2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| C | 0.5 | 0.55* | 0.63 | 0.7* | 0.73 | 0.8* | 0.78 | 0.84* | 0.97 | 1.07* | 1.17 | 1.24* | 1.5 | 1.55* | 1.73 | 1.8* | 1.93 | 2* |

| D | 1.1 | 1.1 | 1.1 | 1.1 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| B1 | 0.2 | 0.2 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.3 | 0.3 | 0.35 | 0.35 | 0.55 | 0.55 | 0.55 | 0.55 | 0.6 | 0.6 |

| B2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| Wire shape | Rect. | Round | ||||||

|---|---|---|---|---|---|---|---|---|

| A1 | 0.63 | 0.5 | 0.5 | 1 | 1 | 1.5 | 1.5 | 1.5 |

| A2 | 1 | - | - | - | - | - | - | - |

| C | 1.27 | 0.66 | 0.7* | 1.32 | 1.4* | 1.78 | 1.78 | 1.78 |

| D | 1.5 | 0.8 | 0.8 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| B1 | 0.3 | 0.3 | 0.3 | 0.4 | 0.4 | 0.7 | 0.8 | 0.9 |

| B2 | 0.5 | - | - | - | - | - | - | - |

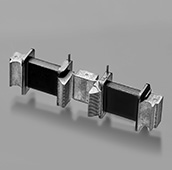

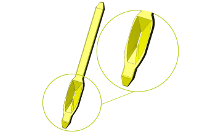

Winged and harpoon pins suit square holes in plastic elements, guaranteeing excellent mechanical resistance of the pins in their seats thanks to its 2 peaks. At the same time the smooth tip of a pin enters freely without any damage.

These pins meet the requirements of automotive manufacturers for connector applications.

ApplicationPlastic connector.

Dimensions

| Wire shape | Square – wings | Square – harpoon | |

|---|---|---|---|

| A1 | 0.63 | 0.63 | 0.63 |

| C | 0.93 | 0.84 | 0.85 |

| D | 1 | 1 | 0.65 |

| B1 | 0.3 | 0.3 | 0.3 |

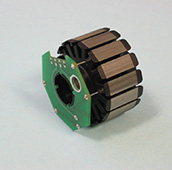

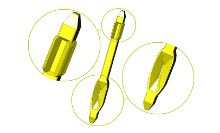

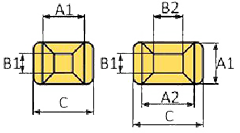

Pressfit flexible geometry matches components with various hole diameter tolerances. It can deal with deviations of + 0.10 to – 0 mm, in compliance with the IEC 352.5 standard.

Size difference between hole and pressfit zone leads to pressfit deformation during insertion. Subsequent сompression of a pin guarantees reliable connection, which doesn’t need to be soldered.

ApplicationDouble-sided printed circuits. Particularly for automotive industry.

Dimensions

| Wire shape | Rectangular | Square | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| A1 | 0.4 | 0.6 | 0.63 | 0.63 | 0.63 | 0.63 | 0.63 | 0.63 | 0.63 | 0.63 |

| A2 | 0.5 | 1 | 0.8 | - | - | - | - | - | - | - |

| C | 0.7 | 1.34 | 1.15 | 1.12 | 1.12 | 1.12 | 1.12 | 1.12 | 1.12 | 1.1 |

| D | 1.8 | 3 | 3 | 1.8 | 1.8 | 2.66 | 2.66 | 3 | 3 | 3 |

| B1 | 0.2 | 0.27 | 0.24 | 0.25 | 0.3 | 0.25 | 0.3 | 0.25 | 0.3 | 0.3 |

| B2 | 0.25 | 0.5 | 0.45 | - | - | - | - | - | - | - |

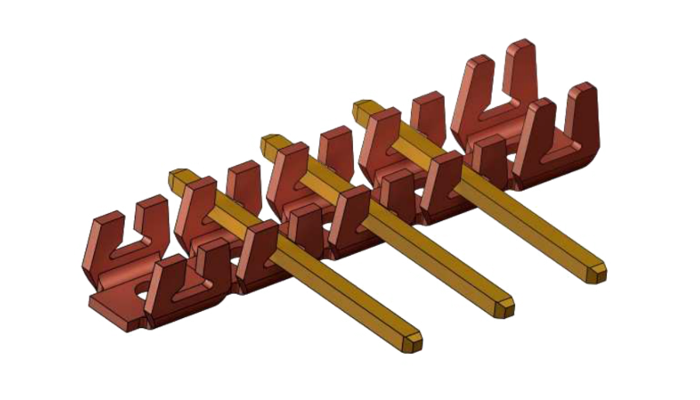

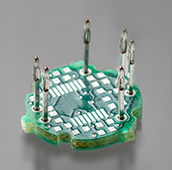

One pin can have several press shapes for direct interconnection of two elements. Pin length, shape and type is defined individually for each connection.

ApplicationStacking of PCBs, stacking of PCBs with a plastic part.

+86- 20-3992 0957

+86- 20-3992 0957

info@smcontact.cn

www.smcontact.cn