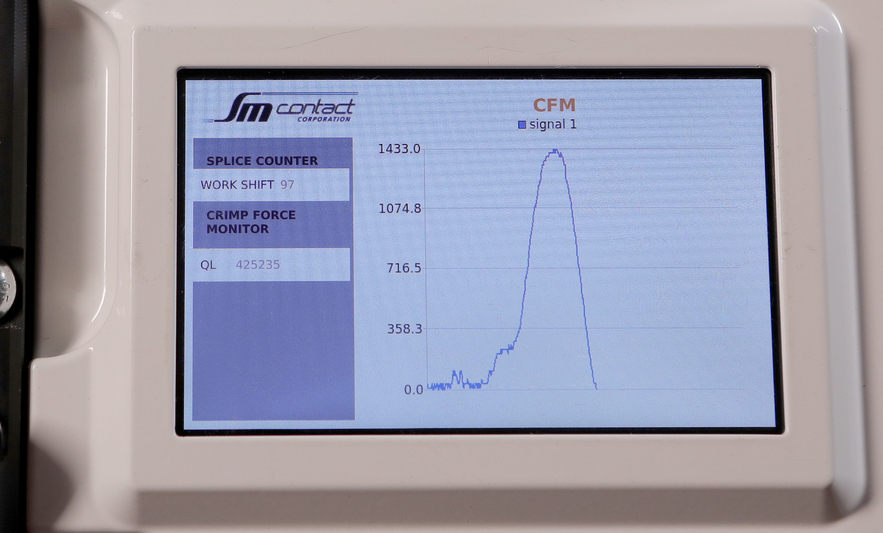

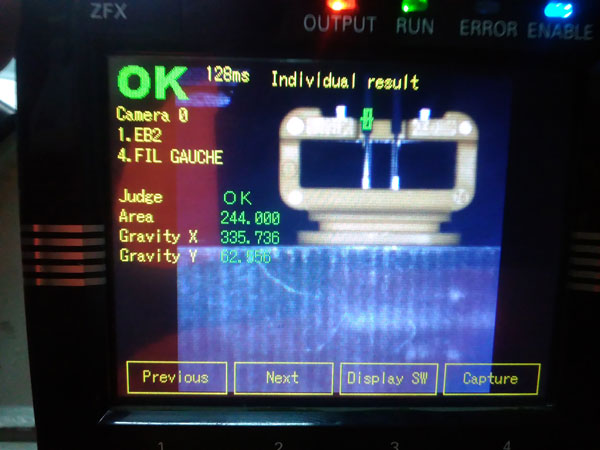

CFM captures, calculates and evaluates force-time curve and detects any deviation from the quality tolerances.

System works with many types of splicing and crimping machines and suites well to any application requiring inline monitoring of forces.

The reference curve of CFM corresponds to crimping force, but in fact it can reflect such quality deviations as:

CFM allows to adjust automatic cutting and/or rejection of defective items.

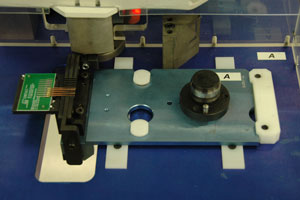

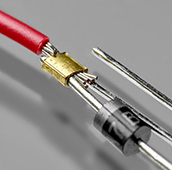

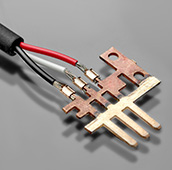

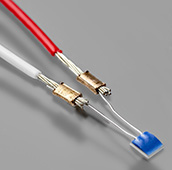

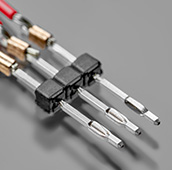

Tooling set includes clincher, anvil, punch, punch guide, and cutting block.

Such parameters as clincher type, clincher size, and punch tip shape are customized for the application.

Inclined clincher surface, smooth cutting surface, quick-change tooling cassette, and finger guard lighting cap guarantees efficient and safe operation.

Data memory in each tooling cassette stores its own tooling list (PN’s) and connection data for up to 10 connections with independent crimp height settings. It enables automatic correction of crimp height when the cassette is installed.

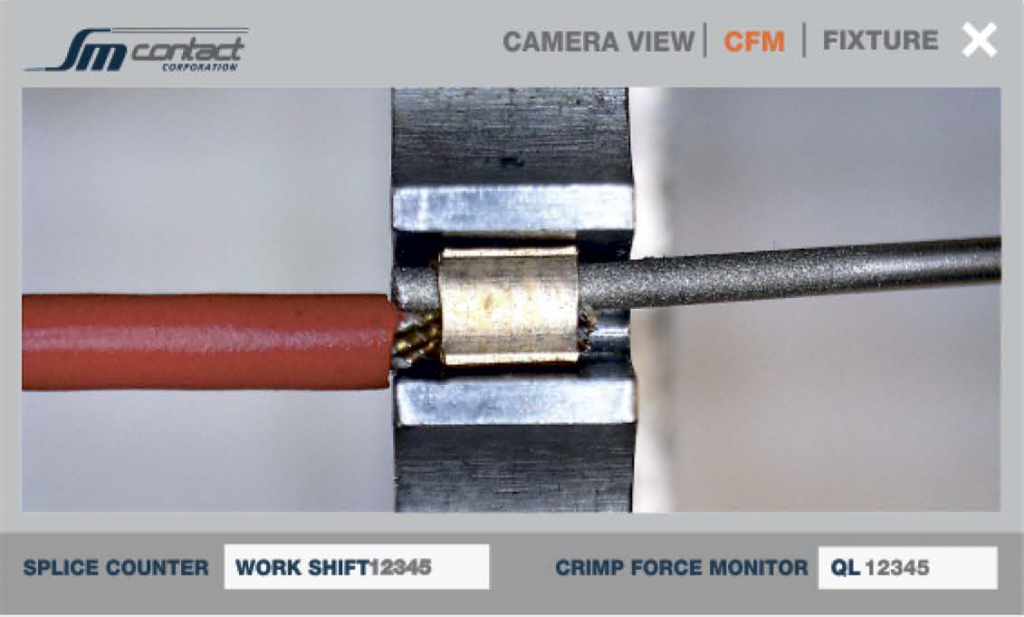

Camera shoots the clincher area and sends video to the HMI screen in real time. Thus, operator can view the components being crimped and is capable to position them in the clincher precisely.

There are two options for the camera placement:

1, built into the tooling cassette,

2, mounted on the left wall of the tooling cassette and connected via USB cable.

RELATED TOPICS

+86- 20-3992 0957

+86- 20-3992 0957

info@smcontact.cn

www.smcontact.cn