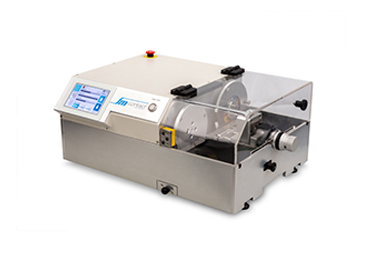

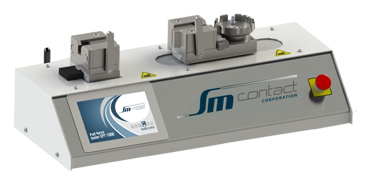

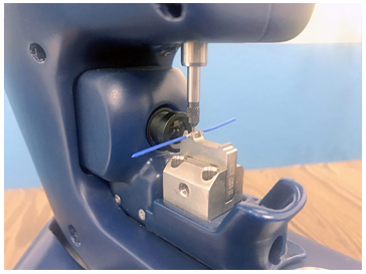

Micrograph laboratory SK 6000 consists of the following separate units: SKT 6000 cutting module, SKE 3000 etching module, and LMX 2000 microscope. This configuration allows measurement of larger components.

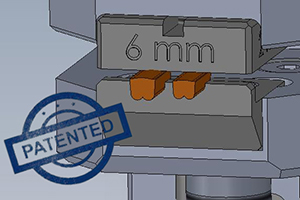

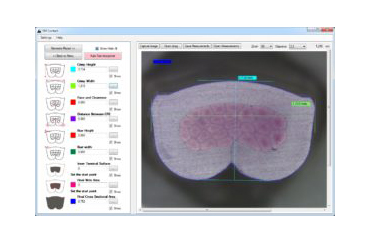

First a sample is cut, its cross-section surface is grinded and etched to make necessary details visible, finally it is located under the optics to get macro image and to measure its parameters. The accuracy of the quality assessment is assured by the patented SM Contact sample holder and Viso 6.00 measurement software.

English

English

Chinese

Chinese

+86- 20-3992 0957

+86- 20-3992 0957