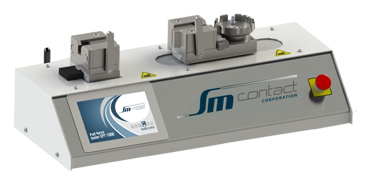

EPT 1000 is a motorized pull force tester for measurement of the pull forces in crimp connections and peeling forces in welding joints.

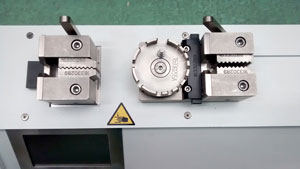

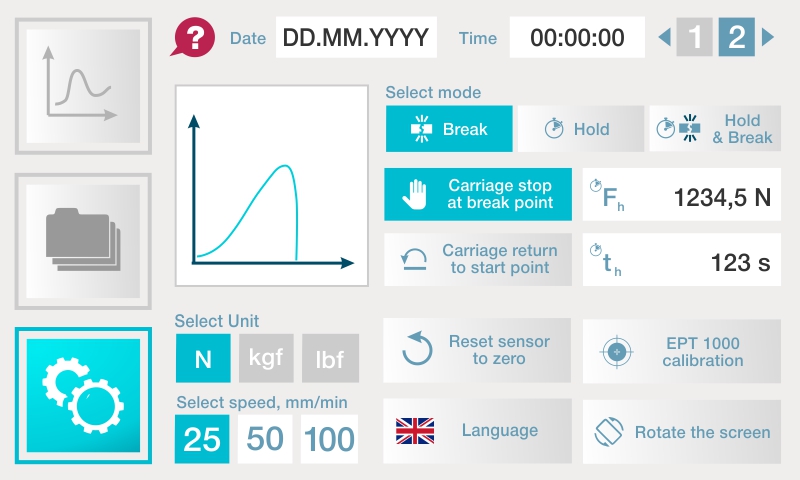

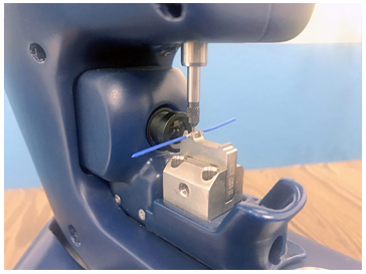

Versatility and ease of use are provided by rotating interchangeable sample holder, long displacement path and intuitive graphical interface. A speed-controlled motor guarantees constant pull speed and accurate results.

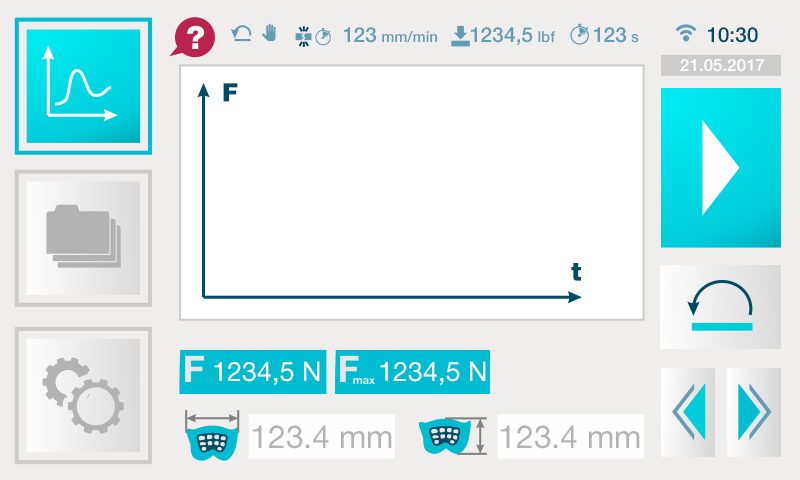

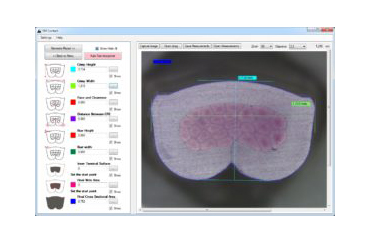

The testing process is visualized on the graphical display in real time, and the results are automatically saved to the archive.

English

English

Chinese

Chinese

+86- 20-3992 0957

+86- 20-3992 0957