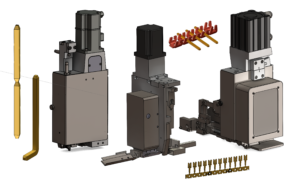

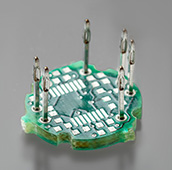

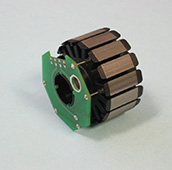

Electrical insertion head

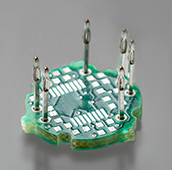

Electrical insertion head is fully interchangeable which simplifies change to the new application. There are several types of insertion heads according to the pin types: end-to-end, right angle, U-band (bandolier) or terminals. Insertion accuracy is highly stable and equals ±0,05 mm (CPK > 1,68).

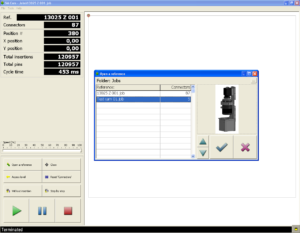

Insertion depth is controlled by encoder and can be programmed to one-hundredth of a millimeter in the PC editor whereas equipment of other brands should be mechanically set. Thus there is no need in mechanical adjustment for each new series.

Insertion technique involves the use of precut round or square wire with acceptable section from 0,3 to 1,5 mm (with servo-drive head) or 1 mm (with pneumatic head).

+86- 20-3992 0957

+86- 20-3992 0957