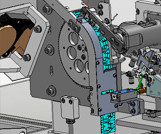

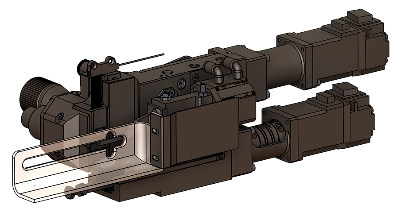

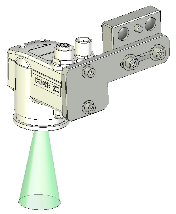

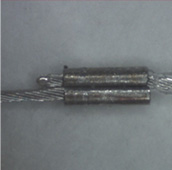

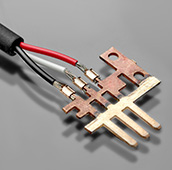

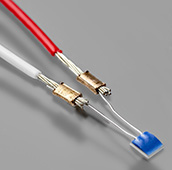

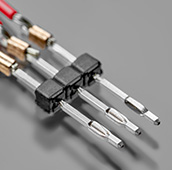

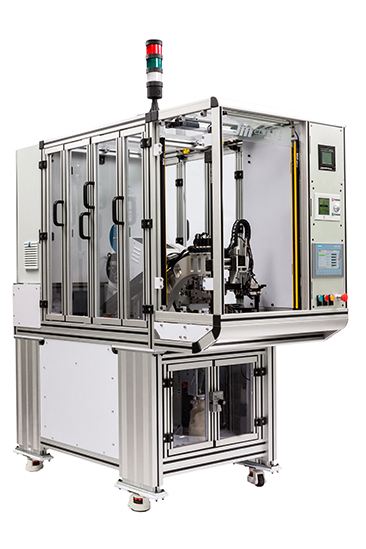

HSCS is designed for high-speed automatic connection of wires and connectors. Feeding of all components is synchronously performed by motorized manipulators.

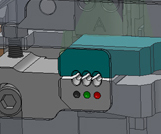

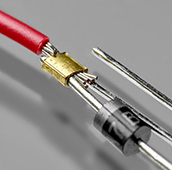

Various additional options are available on demand: straightening, cutting, stripping, twisting, etc. Such quality features as components presence, stripping length, and crimp force can be assured by camera and laser control, CFM and other systems.

Tool cassette can be designed for a wide range of wire cross-sections, e.g. 0.5-1.5 mm2. To perform another connection on the same machine it is necessary to change cassette and tooling.

English

English

Chinese

Chinese

+86- 20-3992 0957

+86- 20-3992 0957